- Agreement combines pioneering UK innovation and Japanese technology with the potential to deliver the largest deployment of negative emissions in power generation anywhere in the world, supporting the UK government’s ambitious target to reduce carbon emissions and enabling clean growth and green jobs.

- Bioenergy with carbon capture and storage (BECCS) at Drax can enable the renewable energy company to become carbon negative by 2030 – permanently removing more CO2 from the atmosphere than is emitted across its operations.

- Mitsubishi Heavy Industries to develop new centre of excellence for Carbon Capture and Use and Storage (CCUS) in London as well as looking at ways to strengthen its supply chain, including the potential production of its proprietary solvent in the UK.

[LONDON/TOKYO] Drax Group and Mitsubishi Heavy Industries Engineering, Ltd., part of Mitsubishi Heavy Industries (MHI) Group, have agreed a long-term contract for Drax to use its carbon capture technology, the Advanced KM CDR process™️, in what would be the largest deployment of negative emissions in power generation anywhere in the world.

The contract, which combines UK innovation and world-leading Japanese technology, will see Drax license MHI’s unique carbon capture solvent, KS-21™️, to capture CO2 at its power station near Selby, North Yorkshire.

Pictured L-R: Kentaro Hosomi, Chief Regional Officer EMEA, Mitsubishi Heavy Industries (MHI); Carl Clayton, Head of BECCS, Drax Group; Jenny Blyth, Project Analyst, Drax Group at Drax Power Station, North Yorkshire [Click to view/download]

The first BECCS unit at Drax could be operational as soon as 2027, supporting thousands of jobs across the North of England as soon as 2024, and capturing and storing at least 8 million tonnes of CO2 a year by 2030.

Drax is the first company to sign a contract to deploy carbon capture technology at scale in the UK. The project combines MHI’s proven and world-leading technology with offshore geological storage under the North Sea, helping the UK achieve its target to cut carbon emissions by 78% by 2035 and demonstrates global climate leadership ahead this weekend’s G7 in Cornwall and of COP26 in Glasgow in November.

As part of the agreement, MHI plans to locate its core CCS team at the company’s European headquarters in London and explore additional employment opportunities in the UK in future. MHI is also looking at ways to strengthen its supply chain, including the potential production of its proprietary solvent in the UK.

MHI BECCS pilot plant within CCUS Incubation Area, Drax Power Station, North Yorkshire [click to view/download]

Will Gardiner, Drax Group CEO, said:

“The world urgently needs to move from making climate pledges to taking climate action. This game-changing contract between Drax and MHI could contribute to a decade of global environmental leadership from the UK and provide further stimulus to a post-Covid economic recovery.Drax Group CEO Will Gardiner in the control room at Drax Power Station [Click to view/download]

“Carbon capture technologies like BECCS are going to be absolutely vital in the fight against the climate crisis. Subject to the right regulatory framework being in place, Drax stands ready to invest further in this essential negative emissions technology, which not only permanently removes CO2 from the atmosphere but also delivers the reliable, renewable electricity needed for clean, green economic growth.”

Kenji Terasawa, President & CEO, Mitsubishi Heavy Industries Engineering, said:

“We are very proud to have been selected as Drax’s technology partner and we firmly believe that our carbon capture technology will make a significant contribution to the UK and wider global community achieving their net zero targets. We look forward to expanding our presence in the UK and developing a centre of excellence for the deployment of carbon capture technology across Europe, the Middle East and Africa region.

“MHI aims to continue reducing greenhouse gases globally by providing reliable and economically feasible carbon capture technology, supported by research and development activity over 30 years and commercial records around the world.”BECCS technology at Drax Power Station, North Yorkshire [Click to view/download]

With an effective negative emissions policy and investment framework from the government, BECCS could be deployed at Drax as soon as 2027 – delivering the UK’s largest carbon capture project and permanently removing millions of tonnes of carbon dioxide from the atmosphere each year.

Drax has already kickstarted the planning process to deploy BECCS at its power station in North Yorkshire – if successful work could get underway to build BECCS at Drax as soon as 2024, with the creation of thousands of jobs.

ENDS

Drax Media contacts:

Ben Wicks

Media Manager (Customers)

E: [email protected]

T: 07761 525 662

Selina Williams

Media Manager (Corporate)

E: [email protected]

T: 07912 230 393

MHI media contact:

Corporate Communication Department

Mitsubishi Heavy Industries, Ltd.

E: [email protected]

Editor’s Notes

-

- Drax aims to deploy BECCS on two of its biomass generating units by 2030 capturing and permanently storing up to eight million tonnes of CO2 a year – a significant proportion of the negative emissions the Climate Change Committee says are needed in order for the UK to reach its climate targets.

- No investment decision has yet been taken and development remains subject to the UK government introducing the right regulatory framework.

- Drax announced it was working on a pilot project with MHI last year to testMHI’s carbon capture technology’s suitability for use with biomass flue gases at Drax

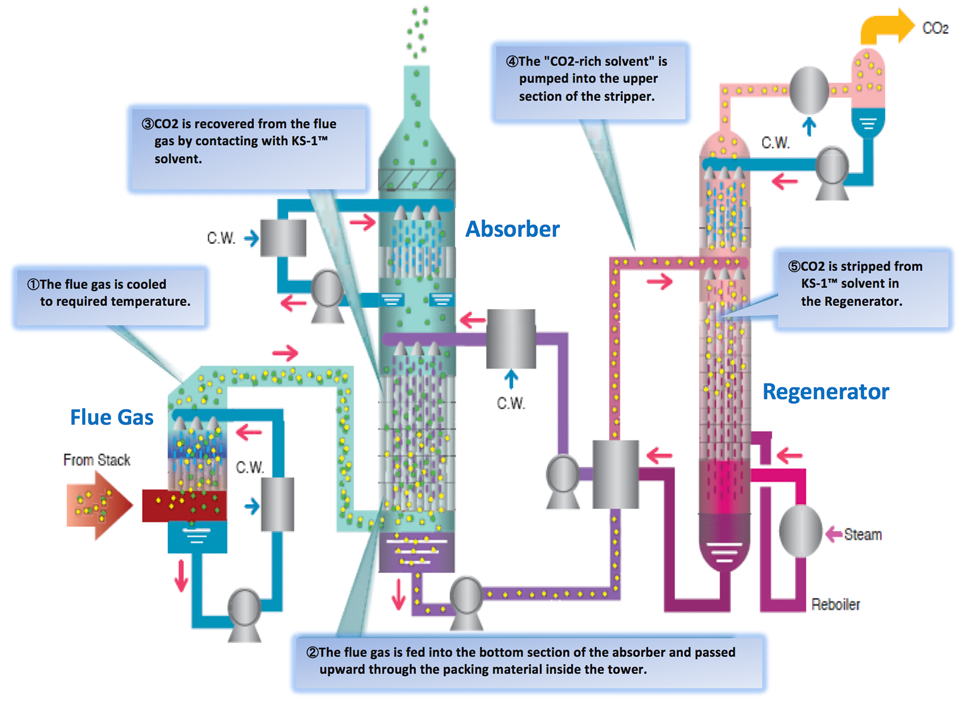

Graphic showing Mitsubishi Heavy Industries (MHI) carbon capture technology process [click to view/download]

- MHI, together with Kansai Electric Power Co., Inc. (KEPCO) started the development of KM CDR Process™ (Kansai-Mitsubishi Carbon Dioxide Removal Process), a post-combustion carbon capture technology, in 1990. As of May 2021, MHI has delivered a total of 13 commercial plants with the KM CDR Process™, with two commercial plants currently under construction, making it a global leader in carbon capture technology deployment. Two more plants are currently under construction.

- The Advanced KM CDR ProcessTM, developed by MHIENG in collaboration with KEPCO, will use a new proprietary solvent, called KS-21TM. Compared to the earlier KS-1TM solvent, which has been adopted at 13 commercial plants delivered by MHIENG, KS-21TM has a number of advantageous properties, such as lower volatility and greater stability against degradation. The newer solvent is also expected to enable reduced running costs and other economic benefits.

- A recent report by leading energy consultancy, Baringa, commissioned by Drax, found that that without BECCS at Drax Power Station the energy system would incur additional costs of around £4.5bn to achieve the UK Government’s fifth carbon budget in 2028 to 2032 – making decarbonisation more difficult and significantly more expensive.

- Drax is a founding member of the Zero Carbon Humber initiative which aims to deploy green technologies including BECCS, Hydrogen and industrial CCS to decarbonise the UK’s most carbon intensive industrial cluster.

- The Northern Endurance Partnership is leading on the deployment of the transport and storage infrastructure needed to permanently lock away the carbon dioxide emissions from industrial emitters in the Humber and Teesside regions.

- Main photo caption: Kentaro Hosomi, Chief Regional Officer EMEA, Mitsubishi Heavy Industries (MHI) at Drax Power Station, North Yorkshire. Click to view/download here.

- What is bioenergy with carbon capture and storage (BECCS) animation can be viewed in widescreen (16:9) here (download link) and square (1:1) here (download link).

- B-roll video can be viewed below and downloaded here

About Drax

Drax Group’s purpose is to enable a zero carbon, lower cost energy future and in 2019 announced a world-leading ambition to be carbon negative by 2030, using Bioenergy with Carbon Capture and Storage (BECCS) technology.

Its 3,400 employees operate across three principal areas of activity – electricity generation, electricity sales to business customers and compressed wood pellet production and supply to third parties.

Power generation:

Drax owns and operates a portfolio of renewable electricity generation assets in England and Scotland. The assets include the UK’s largest power station, based at Selby, North Yorkshire, which supplies five percent of the country’s electricity needs.

Having converted Drax Power Station to use sustainable biomass instead of coal it has become the UK’s biggest renewable power generator and the largest decarbonisation project in Europe. It is also where Drax is piloting the groundbreaking negative emissions technology BECCS within its CCUS (Carbon Capture Utilisation and Storage) Incubation Area.

Its pumped storage, hydro and energy from waste assets in Scotland include Cruachan Power Station – a flexible pumped storage facility within the hollowed-out mountain Ben Cruachan.

Pellet production and supply:

Drax owns and has interests in 17 pellet mills in the US South and Western Canada which have the capacity to manufacture 4.9 million tonnes of compressed wood pellets (biomass) a year. The pellets are produced using materials sourced from sustainably managed working forests and are supplied to third party customers in Europe and Asia for the generation of renewable power.

Drax’s pellet mills supply around 20% of the biomass used at its own power station in North Yorkshire, England to generate flexible, renewable power for the UK’s homes and businesses.

Customers:

Through its two B2B energy supply brands, Haven Power and Opus Energy, Drax supplies energy to 250,000 businesses across Britain.

For more information visit www.drax.com

About Mitsubishi Heavy Industries Group

Mitsubishi Heavy Industries (MHI) Group is one of the world’s leading industrial groups, spanning energy, logistics & infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world.

For more information, please visit www.mhi.com or follow our insights and stories on www.spectra.mhi.com.

About Mitsubishi Heavy Industries Engineering, Ltd.

Mitsubishi Heavy Industries Engineering, Ltd. (MHIENG) includes the engineering business of the chemical plants and transportation systems of Mitsubishi Heavy Industries and extends them with newly added environmental facilities (CO2 Capture Plant). MHIENG has provided numerous Engineering, Procurement and Construction (EPC) projects covering large-scale infrastructure, such as chemical plants, environmental plants, and transportation systems, in many countries and regions around the world. The Company readily meets diversified customer expectations by undertaking all phases from project planning to basic design, detailed design, procurement, manufacture, construction, commissioning, after-sales service, and Operation & Maintenance (O&M), and capital participation in businesses.

For more information, please visit the Company’s website: https://www.mhiengineering.com/